Tonight not only our big garden project reached a milestone (wall done, earth back in place) the Frej Kayak project also made a big step forward.

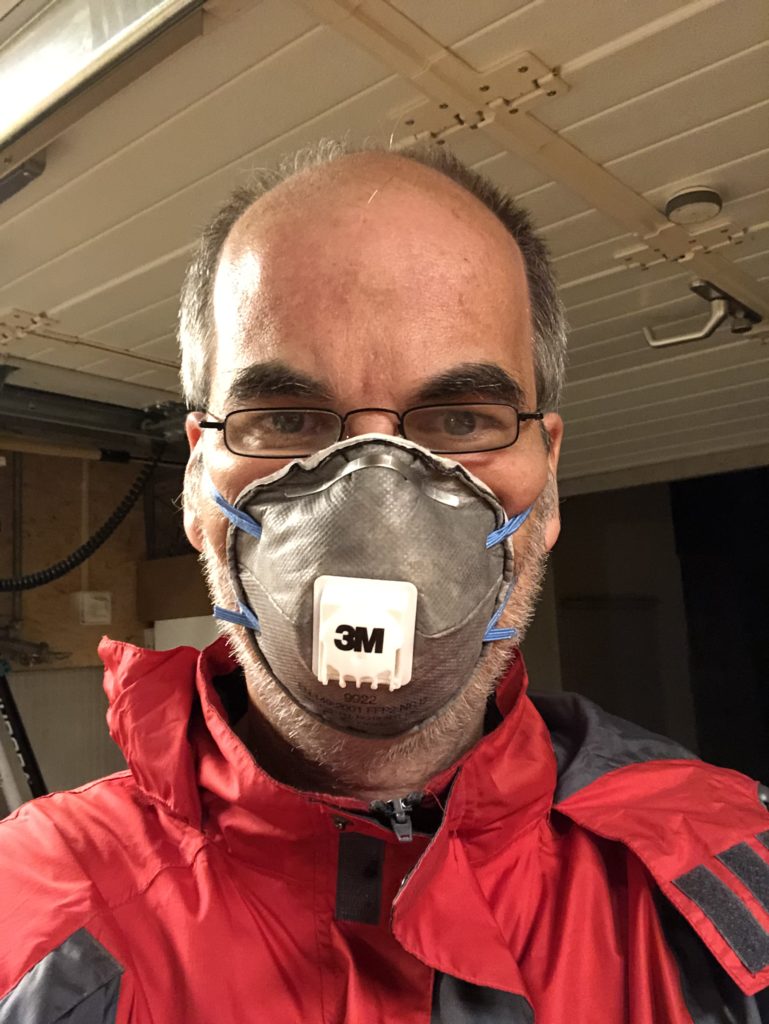

BUT: Saftey first…

For all of you, who don’t care… you only have one health and epoxy resin is serious stuff. So wear gloves and mask against organic and an-organic fumes and old cloth. Saftey glasses also make sense but I don’t work from underneath – so I skipped that one!

Placeing the fiberglass cloth is simple if you hang them above the building place like I did. You simply unroll the amount you need… similar the concept of toilet paper – only that you have to cut it…

PICTURE OF ROLE (soon to come)

I recommend a sharp scissor and cutting the cloth PRIOR you get the epoxy mix ready.

I use my favorite epoxy – West 105/206 resin/hardener. The 206 is the “slow” hardener – what gives you plenty of time (pot time) before curing starts. I like the pumps you can put on the epoxy canister. These pumps have the perfect 1:5 mixing ration – you just have to be able to count (equal strokes = equal mixing) and to stir.

PICTURE OF WEST EPOXY (soon to come)

After 2h preparation & working the hull is glassed!

What looks like a crack in the bow is the overlapping glass cloth. I pre-cutted the cloth and overlapped them during application of epoxy. This adds a little more strength the bow and stern.

I try to achieve a wet but structured look of the cloth with no “milky” spots. Milky means the cloth is not totally wet and therefore not sticking to the wood properly. If it looks painted (no structure visible) you use too much epoxy and you need to sand (did I mention, that I hate sanding?).

Next to the hull you see the deck with glass cloth put back. During sanding one weak glue joint came apart and I had to fix it. I noticed it during preparation and cutting of glass because of an unusual longitudinal buckle in the cloth… It went fare to well so fare with the power tool – and epoxy is no fun to sand by hand (takes you hours). I hate orbital sander as well! 🙁

So far so good! With sanding and glassing I am currently logging 30hours build time.

Glassing of the deck went better but not perfect. Next boat (I have to do two of them) will be better.

As mentioned earlier, I have some spots, where the epoxy is not fully wetting the fabric. Not sure what to do. Probably sanding it down and put a patch of fabric over it. Did I mention how much I like sanding?

Stay tuned!

Best Regards,

Axel

![Frej – Start glasing the Kayak Tonight not only our big garden project reached a milestone (wall done, earth back in place) the Frej Kayak project also made a big step forward. BUT: Saftey first… For […]](https://www.holzbootsbau.ch/wp-content/uploads/2019/04/img_0020-e1554755559943-620x250.jpg)

Leave a Reply