Usually I write in German – but this time I will document the build process in English having the illusion that more people might read this page!

Selection of Design

Since the age of 5 both of our daughters paddle independetly into their “Greenlander 4 Kids” Designs. The “Greenlander 4 Kids” is my design very much based on a Greenland Style Kayak.

Kids grow and naturaly our older daugther is 13 years when I write this lines and in summer 2018 she requested a new Kayak for her since she had difficulties to put her legs into the boat. We finished the saison and removed the seat and foot rests to have a little more room. But in the end we had to talk about the new kayak. And I have to build two of them.

It is a whole different thing to talk to 13 year old teenager with 8 years of paddle experience about how the new kayak should look like. The end was a long list of attributes and requirements. Some can be found here:

- Color – Must be Yellow / White and must look great (Girls?)

- Minimum Drag, Fast, low volume but suitable for day-tripping

- Low Siluette and Modern Lines (“We could build a Skin-on-Frame when I want go back to Greenland Style boats…” was her quote)

- Good manouverability and good handling

- Low back dack and close to the water for roleing (She wants to master it next summer)

So I looked into my drawing archive and surfed the www… and I was again and again attracted by the way Ulf Johansson designed and build his Kayaks (https://www.johanssonkajak.com/?cat=6) – with my strong connections to Sweden I also put Björn Thomasson’s Designs into concideration. From my experiences in paddling and as a Naval Architect the lines of Ulf told me, that he is a much better paddler than I am and that his designs are focussing on Seakayak Racing and fast traveling. He features a nearly round main center section. I was not willing to take that risk and aimed out to the more classic rounded “V” shape of the main center section. This shape provides significant bigger initial and secondary stability with not too much additional drag. During this process of conceptual design I decided to not draw the kayak my self and narrowed in onto the “FREJ” from Björn Thomasson. This design is actually build by Struer Kayaks in Danmark and my daugther liked the look…

In the End Björn and I found an agreement for a customized version of his “Frej” Design. He provided me a paper set of drawings and a digital set of the drawings and first license to build one of the boats. He actually “spread” the offering for the “Frej” in a range from “S”, “M” to “L”. I will buy another License for our younger daughter when she is done with her Greenlander…

Digitalization on the Shopfloor

One reason for not drawing the design myself is my study beside my job. I am going to be a “Master in Digital Tranformation”. Means for me Digital Manufacturing is every day job and I apply this not only to my professional life.

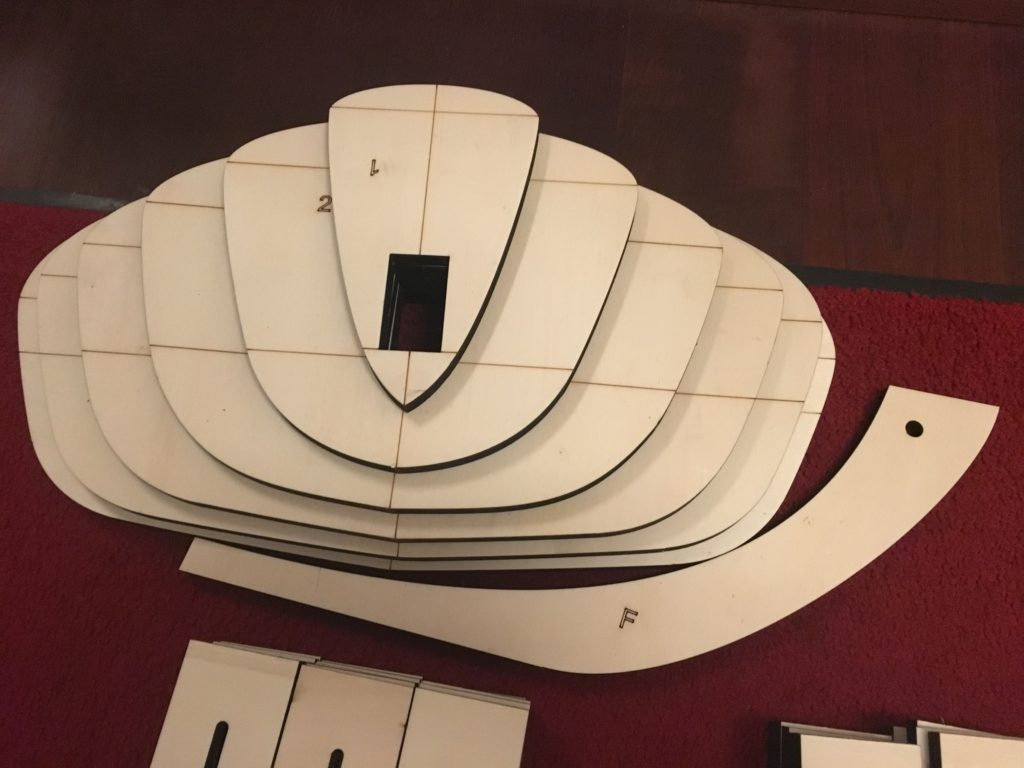

So I used laser cutting to cut out the cross sections of the new boat. Björn provided me the DXF/PDF of the drawings and I prepared his design for my trusted laser cutting company (known from my other hobby – Model Rail Road). A few weeks later – yesterday – the package with the cutted sections arrived.

Bow and front Cross Sections

Clamping aids

Stem

Stem and tail Cross Sections

I am quite happy with the results – the Laser Gang and Harald did a good job! All the markings appeared clear and the sections are super precise as expected. Sitting one hour in front of the computer instead of standing 5-8 hours in the shop to cut the sections and produce saw dust is a good trade in for 150.- €

At least for me and my super tight time budget. I also will employ 3D Printing in plasic and metal for some of the details. But later more on that.

Next will be the Strong Back. I will utilize a strong Aluminium profile from special vehicle construction industry to make my life easier and the boat straight.

Update 10.Dec 2018

Today I ordered the Aluminum Tube for the Strongback. I decided to go for a 32mm x 112mm AlSiMgMn Profile suitable for Vehicle Design.

Looking forward to pick it up on the 19th of December…

Stay tuned & Best Regards,

Axel

![Frej – Preparation to Build Usually I write in German – but this time I will document the build process in English having the illusion that more people might read this page! Selection of Design […]](https://www.holzbootsbau.ch/wp-content/uploads/2018/11/img_3074-620x250.jpg)

Leave a Reply