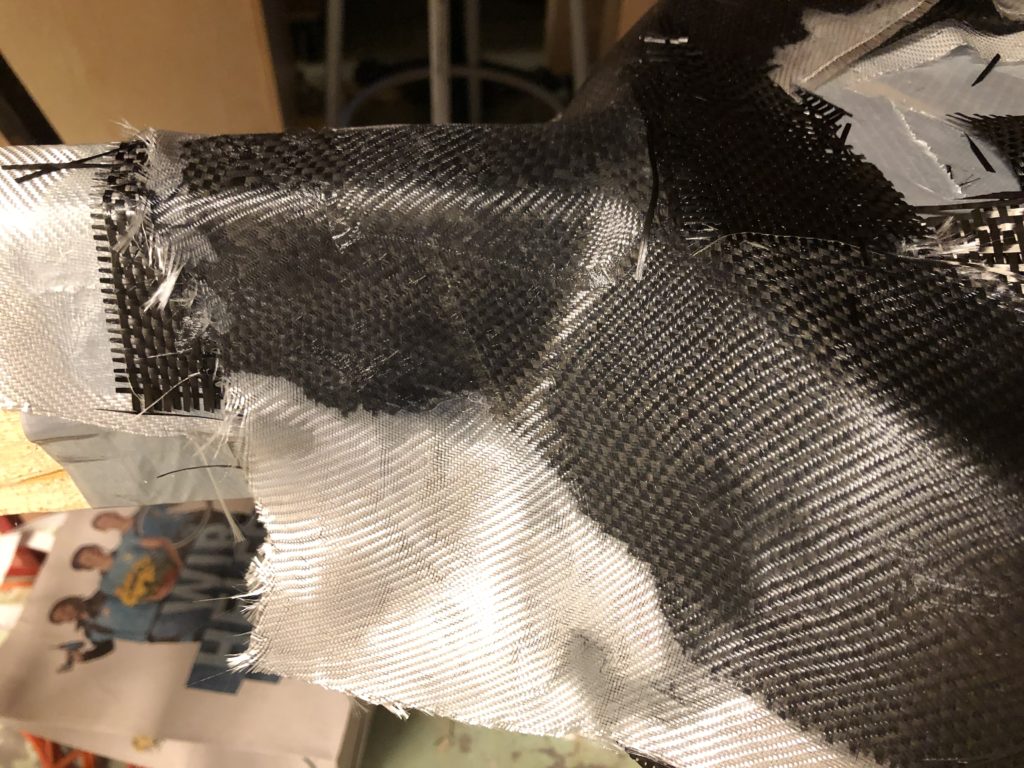

Beeing a seakayak, the boat needs sections and hatches. I bought the 20cm round hatches from kayak sport. For the form parts, that carries the hatches, I followed the usual way and created a basic for from extruted styreen (XPS) and the final form in carbon fiber.

The scariest moment is to cut a large hole into the boat. And it went wrong. Not terrible but bad and enoing enogh. Pictures later in the process…

Update 08.05.2019

As mentioned – here are the pictures of my fault and how to avoid them.

I cutted away too much of the material. Not a too big of a problem and I can repair but it is a bit frustrating…

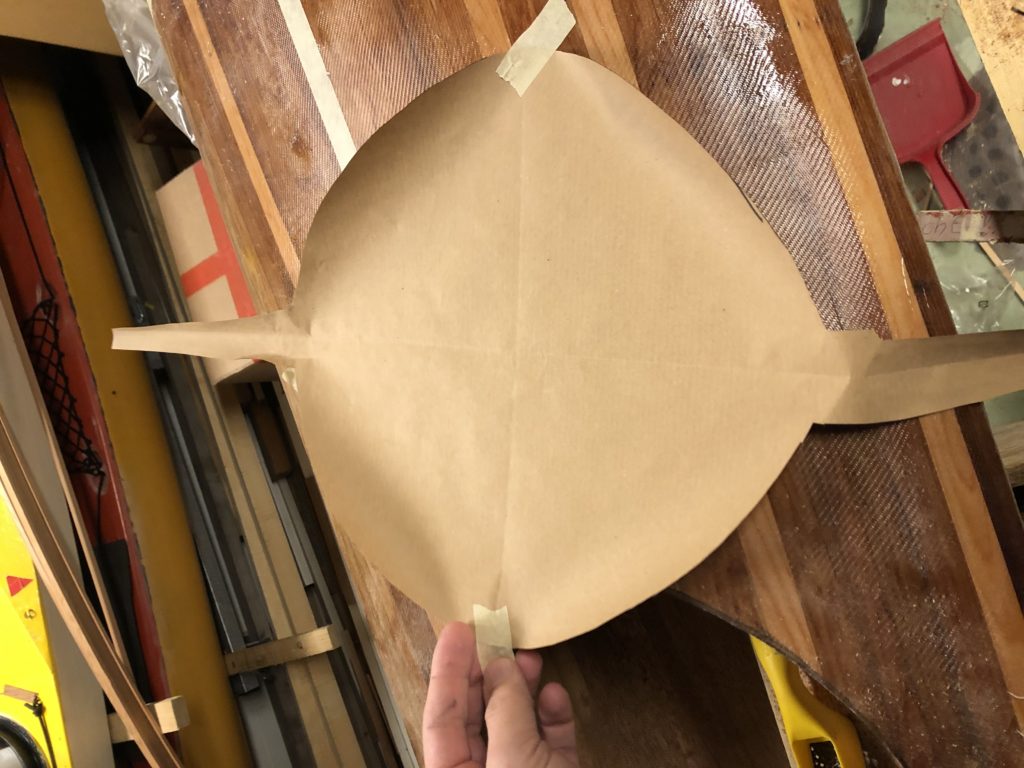

To avoid this, I used a paper template of the form and traced that one to the hull and cutted than UNDERSIZE to avoid this happing again.

if you use a sharp router bit…

Best Regards,

Axel

![Frej – Adding the hatches Beeing a seakayak, the boat needs sections and hatches. I bought the 20cm round hatches from kayak sport. For the form parts, that carries the hatches, I followed the usual […]](https://www.holzbootsbau.ch/wp-content/uploads/2019/05/img_0146-e1557332930144-620x250.jpg)

Scary thing it is to make holes in hull and deck. Have you found my build log (swedish only) of my recent build? For instance this: https://frejbygge.blog.se/besvarliga-luckhal/

Hi Jan – thank you for your suggestion.

Good content 🙂

For me it is always scary to cut a hole into a wooden boat.

Best Regards,

Axel